Saved Bookmarks

| 1. |

Explain contact process. |

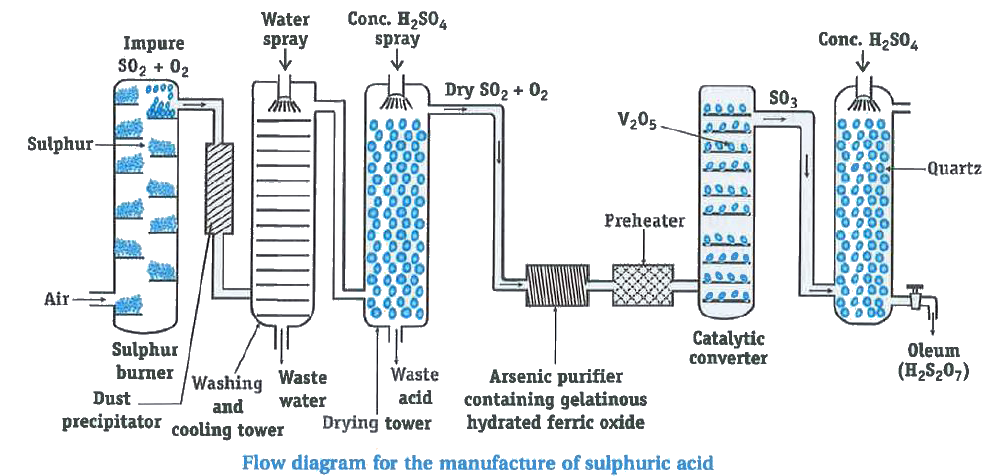

Answer» Solution : In contact process, the following steps are involved : (i) Burning of sulphur or sulphide ores in PRESENCE of air to generate `SO_2`. (ii) Conversion of `SO_2` to `SO_3` by the reaction with oxygen in the presence of a catalyst (`V_2O_5`). (iii) Absorption of `SO_3` in `H_2SO_4` to give oleum (`H_2S_2O_7`). The `SO_2` produced is purified by removing dust and other impurities such as arsenic compounds. The key step is the catalytic oxidation of `SO_2` with `O_2` to give `SO_3` in the presence of `V_2O_5` (catalyst). `2SO_(2)(g) + O_(2)(g) overset(V_(2)O_(5))to 2SO_(3)(g), Delta_(r)H^(-) = -196.6 kJ//mol^(-1)` The reaction is EXOTHERMIC, reversible and the forward reaction leads to a decrease in volume. Therefore, low temperature and high pressure are the favourable conditions for maximum yield. But the temperature should not be very low otherwise. In practice, the process is carried out at 2 BAR pressure and 720 K temperature. The `SO_3` gas from the catalytic convertor is absorbed in concentrated `H_2SO_4` of the desired concentration. In the INDUSTRY, two steps are carried out simultaneously to make process continuous and cost effective. `SO_(3) + H_(2)SO_(4) to H_(2)S_(2)O_(7)` (Oleum) The sulphuric acid obtained by contact process is 96-98% pure. |

|

Discussion

No Comment Found

Related InterviewSolutions

- Which of the following compounds is not cleaved by HI even at 525 K ?

- To a 25 mL H_(2)O_(2) solution excess of an acidified solution of potassium iodide was added. The iodine liberated required 20 " mL of " 0.3 N sodium thiosulphate solution Calculate the volume strength of H_(2)O_(2) solution.

- The suggested mechanism of a reaction is : (a) A+BhArrD("fast) "(b)A+Drarr2C("slow")Write the balanced equation of the reaction if its experimentally deduced rate equation is , rate k=[A]^(2)[B] Find the intermediate formed during the course of the reaction . Does the predicted rate law from the mechanism match the experimental rate law ?

- Which of these changes with time for a first-order reaction A Rate of reaction B . Rate constant C . Half-life

- What is the hybridisation of central atom in the product obtained along with hydrofluoric acid when complete hydrolysis of Xenon Hexa Fluoride takes place ?

- Which of the following amino acid forms sulphide bond in polypeptide

- Which of following pair is Diastereomers:

- What is the major product of the following reaction CH_3C-=C-CH_2-CH_3overset("1 mole of " Cl_2)to

- Which polymer is used in petrol tank linings ?

- Which of the following carbohydrates are branched polymer of glucose ?