Saved Bookmarks

| 1. |

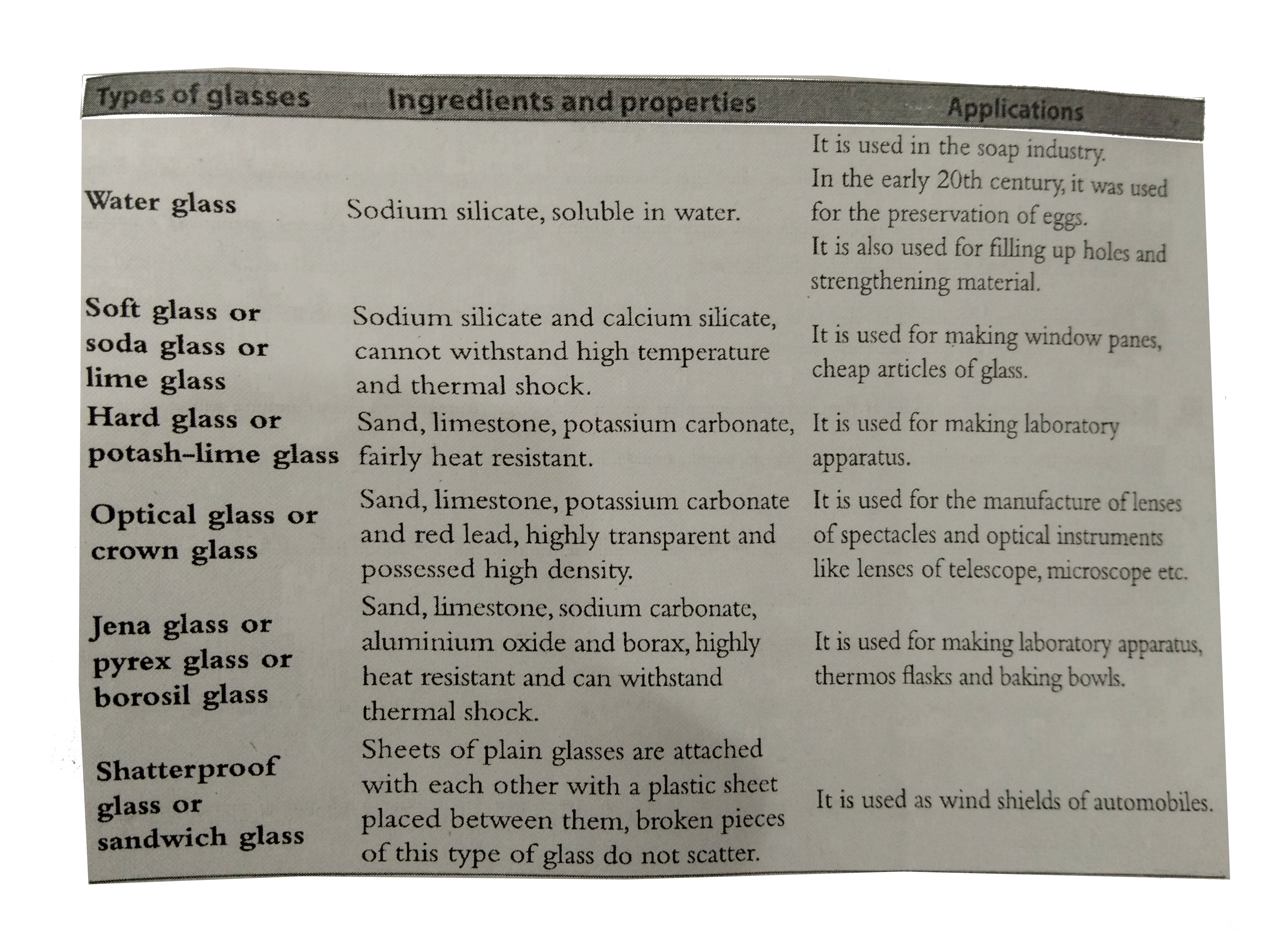

How is glassmanufactured? Mention different types of glass, their ingredints, properties and application. |

|

Answer» Solution :Manufacture of glass : Glass is made up of silica or sand, limestone, feldspar as MAJOR rew material. Broken pieces of glass called culled culletare added to the RAW material. Some other ingredients like red LEAD, aluminium oxide, manganese oxide, chromium oxide etc are used to impart specific characteristics to glass. The rewmaterials are mixed in the required proportion and melted in a glass tank furnace or pot furnace. Cullet initiates the melting process at a lower temperature. Three major techniques are applied on the molten glass obtained in the process of melting for the manufacture of different products of glass. (i) Blowing of glass : This technique is used for the manufacture of laboratory glassware, bottles etc. (ii) Optical glass : Molten glass is pressed into circular shape from which different optical glasses are manufactured. (iii) Sheet glass/float glass : Molten glass obtained from theglass tank furnace is PLACED on molten bath of tin. Themolten glass spreads on the bath of molten tin with uniform thickness from which sheet glass/float glassis drawn. The different shapes of molten glass obtained from the above three techniques are then subjected to cooling process called annealing at controlled temperature in a longtunnel type annealing chamber. General properties of glass : Glass is a supercooled liquid. Molten glass obtained from glass manufacturing furnaces is allowed to cool down slowly. During cooling , viscosity of glass increasesmanifolds below therange of its freezing temperature and loses itsability to flow. Hence it appears like solid. Glass is transparent, highly chemical resistant, a bad conductor of heat and electricity and it can be easily MOULDED into desired shapes.

|

|

Discussion

No Comment Found

Related InterviewSolutions

- Which of the following phenomenon is an effect acid rain ?

- Which of the following can be used to reduce suspended particulate matter in atmosphere in mine areas ?

- What are noble gases ? Mention their uses.

- What will be the formula of the sulphate and sulphite of a trivalent metal that isM^(+3) ?

- Which among the following is an element ?

- Xenon and krypton is used in electric bulbs to slow down the sublimation of tungsten.

- Whichof the following substances does not form a curdy precipitate when it is added to hard water ?

- Why are droplets of water observed on the walls of a glass tumbler containing ice ?

- What are homogeneous and heterogeneous mixtures ? Give one example for each.

- Which among the following is true regarding aqueous solution of sulphur trioxide and sodium oxide?